ARCKIT Model 20

“We forget that the water cycle and the life cycle are one.”

Introduction

In this "Net Zero" blog series we learned that the highest sustainability rank that a building can achieve is Net Zero. This means that the building or structure relies completely on exceptional energy conservation and on-site renewable generation to meet all of its heating, cooling and electricity needs. This series specifically concentrates on the Living Building Challenge (LBC) and how it strives to create a "socially just, culturally rich, ecologically restorative" environment for us to inhabit. Instead of thinking of a world that is less bad, the LBC asks the profound question...

"What does good look like?"

Over the course of this series, we will be going into detail on each of the seven LBC Imperatives; Place, Water, Energy, Health and Happiness, Materials, Equity and Beauty. Each of these imperatives are known as "petals," relating architecture metaphorically to a flower, the shining symbol of an ideal built environment.

Water Petal Intent

We must take into consideration the extreme importance of water. It is an abundant commodity that deserves the respect of a rare, precious resource. We have to realign how people view/use water and redefine "waste" in the built environment. 70 percent of the earth is comprised of water and only 2-3 percent of that is fresh and drinkable. This number is diminishing at an alarming rate and many countries are facing severe water shortages on top of terrible water quality. Regions that have avoided these problems due to the historical presence of fresh water are soon to be at risk if we continue to allow unsustainable practices and an exponentially increasing drawback of major aquifers.

Currently, the Living Building Challenge sees a future where all developments are designed and configured based on their specific site carrying capacity. To state it simply, the site will have to harvest a sufficient amount of water that at a minimum, meets the needs of the ecosystem that the development occupies as well as those of its neighbors. In some areas, this would mean that harvested water would be stored, used, purified and used again. This cycle would be able to repeat itself endlessly in a perfectly confined and monitored system. Unfortunately, we don't live in a perfect environment and such practices are even illegal due to health/land/building regulations and ownership of water rights. To reach an ideal goal for water use, the LBC states that we must "challenge outdated attitudes and technology with decentralized sites - or district-level solutions that are appropriately scaled, elegant, and efficient." Simple? No. A lot of additional work goes into planning Net Zero developments and at this point in time, people aren't motivated enough to go that extra step.

Net Positive Water Imperative

With the Water Petal Intent, there is only one imperative: Net Positive Water. A project must use and release water in such a way that it works in harmony with the surrounding environment. Over 100 percent of the building or development's water needs must be met and supplied by "captured precipitation" or a natural closed loop system. Both ways must allow for recycled usage and purification without chemicals. "All storm water and water discharge, including grey and black water, must be treated onsite and managed either through reuse, a closed loop system, or infiltration." While a simple idea to ask for, such a system relies on a complex framework and incredible placemaking.

“Filthy water cannot be washed.”

Case Study

Omega Center For Sustainable Living

The Omega Center for Sustainable Living (OCSL) is a combined water filtration facility and learning center at the Omega Institute for Holistic Studies in Rhinebeck, New York. OCSL provides an innovative and educational experience that aims to demonstrate and teach what is possible through regenerative thinking and a "design that awakens the best in the human spirit."

“Omega is thrilled to have crossed the finish line, and hopeful that projects like ours will mark a new era in sustainable design, one that reflects a truly integrated approach to creating built environments that are in harmony with the natural world”

BNIM Architects, commissioned by The Omega Institute, designed the OCSL, a new 6,200 square foot facility that rests on a 5 acre site, to serve as a new and efficient waste water treatment facility. Replacing the existing wastewater disposal system, the OCSL needed a novel way of controlling the water footprint of a 195 acre campus. BNIM Architects went above and beyond with the design to allow the OCSL to be apart of the campus' education initiative by including classrooms and treatment cells called the "ECO Machine" that would be open to the public.

Materials used and air quality during and after the construction process were very important to the project team. Careful considerations and a long vetting process was taken to know the source, composition and impacts of each material. In many areas of the building, the materials are left exposed since the building was designed to minimize the use and need for surface treatments. It was made clear that all regularly occupied spaces must have access to "operable windows" and rooms that are naturally ventilated. Even during the construction process, the team kept the construction site clean by sealing off all materials and spaces, making sure to eliminate dust accumulation.

To meet the building's energy and water needs, the team installed three solar arrays that feed powered directly to the building and large cisterns that collect all the roof water runoff. With an obvious focus in water management, the OCSL takes in potable water from the entire campus' underground wells and runs it through the "ECO machine" system for treatment where it is eventually returned to the ground to be used in bathrooms, sinks an drinking fountains. The non potable water from the roof, collected in the cisterns, allows the OCSL to have a reserve for 100% of the building's non potable water use during the year. "On demand, water is pumped from the cistern to a holding tank and UV sterilizer. From the holding tank, rain-water is distributed to its usage location. After use, this water is passed through to the ECO Machine system for treatment and eventually returned to the ground via subsurface dispersal." The toilets, hoses and other irrigation devices are run off of this system. In total the Eco Machine treats about 3 million gallons of water from the Omega campus every year.

The Omega Center for Sustainable Living is an amazing structure that highlights the strengths and power a Living Certified building can have on a community. As a multi-use facility that controls and monitors the entire campus' water usage, the building serves an educational purpose, bringing people a hands on and personal educational experience with one of the worlds most environmentally conscious designs. Leaving a footprint that cannot be seen may be our biggest thank you we can offer to nature.

Diagramming

Project Details

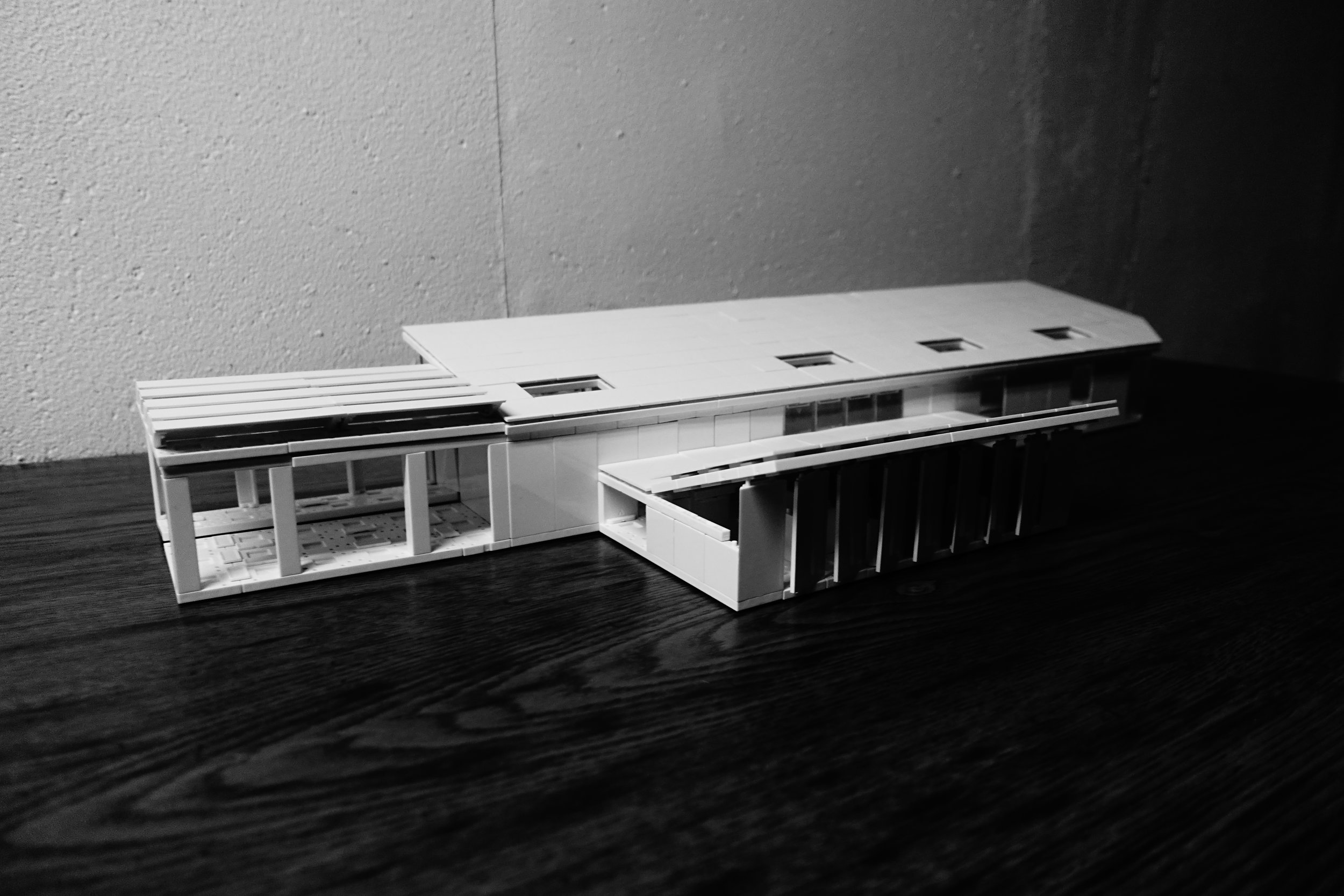

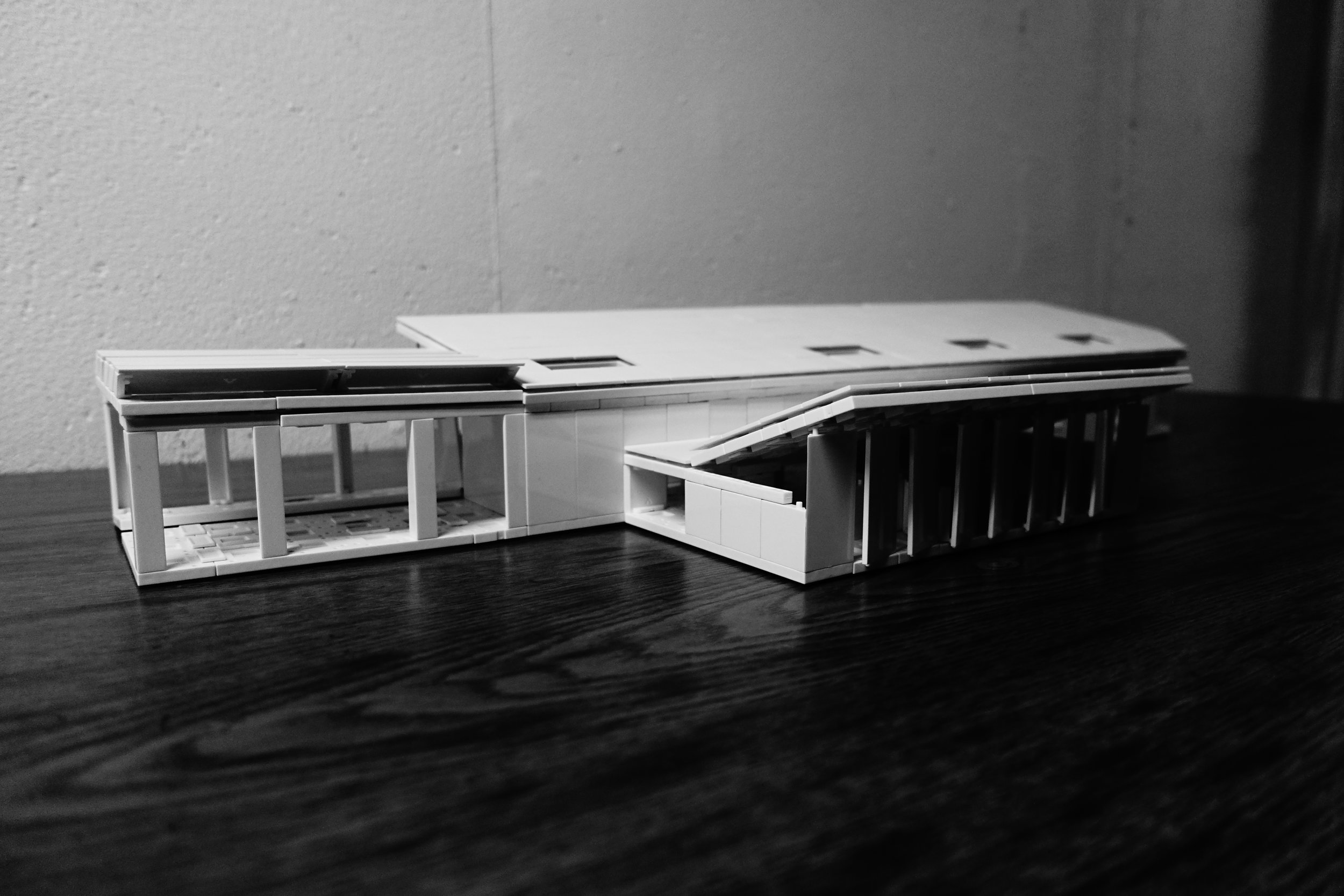

When figuring out the dimensions and laying out the Arckit components, I didn't realize how massive this building is! To build the model at a reasonable size and also be efficient with the amount of parts I own, I changed the standard scale of 1:48 to 1:96. This means that each unit in Arckit represents 8 FEET or 2.44 METERS! As I was working at this scale for the first time, I was able to make some very interesting touches to really bring the model together.

Programming of Space

When building with Arckit, I always recommend starting off with a base plate. By knowing the amount of floors in the model you are trying to create, you need be wary of your resources as to be able to duplicate that base plate as many times as needed to create multiple floors and the final roof. After figuring out the proper dimensions, this model was quite simple to build. I is mainly just one extremely big open space, and several smaller rooms. I put all of the perimeter walls down and set down all the spaces for windows and then put walls down to divide up the individual areas. I created an uneven wall distribution to allow for the two large sloping butterfly roofs. Over the lobby and the atrium space, I used the half wall sections to elevate a parapet roof sections connecting the two butterfly wings. For the ECO machine, I created elevated tables that would align with my section cut of the building. To build the tables, I used the basic floor and ceiling panels and layered two on top of each other. Above the patio, I recreated one of the flat solar arrays by using the roof extender trusses and the roof truss tiling. This created a very visual angled texture that represented the space very well.

Overall this was both a challenging and fun model to build. I got to play around with many pieces I don't normally use and see new ideas for future models. To see everything that I did, make sure to watch the video documentation video linked below. When I am filming just myself building, I have more freedom to bring closer angles and and more thought out shots.

Photo Gallery

Video Documentation

“When the well’s dry, we know the worth of water.”

Notes

If you have any questions, suggestions or comments, I would love to hear from you in the comments section below or through email at rikysongsu@gmail.com.

For more information regarding Arckit visit www.arckit.com or to see all the models visit www.rikysongsu.com/model

Thank you!